Actuator

March 23, 2022

BDT-X Bi-Directional Creels

March 23, 2022Carbon Fiber Analyzer

Request Info & PricingGet a Quote

For analysis of carbon fiber characteristics and carbon fiber quality control. Analysis of fiber tow width, filament breakage, fiber tension, etc.

For laboratory / pilot line use (CFA-F), as well as for monitoring fiber on carbon fiber production lines (CFA-Lite).

Simple data acquisition (USB type media or SD card) or on-line data acquisition via PC supplied for monitoring and data logging.

Description

CFA-Lite (for in-line monitoring)

This system to be used in-line for carbon fiber production quality monitoring.

- Width sensor: Via optical micrometer width sensor

- Fiber Width: 25mm maximum

(*) Please consult Izumi International, Inc. if wider rages are required. - Speed: Max 10m/min

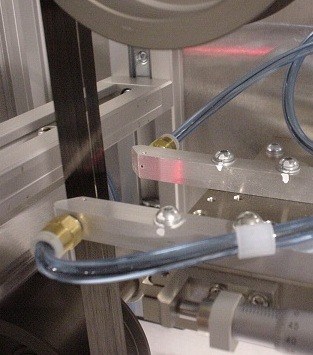

(*) Please consult Izumi International, Inc. if higher speeds are required. - Filament breakage sensor (optional): Thru beam type fiber optic sensor

Minimum filament diameter detection is 0.007mm diameter.

Operator interface: HMI provides real time reading of fiber width in mm. - Data acquisition: System records data to a USB data stick to enable viewing of logged data via PC after

data collection. - Electrical: 110VAC single phase

(*) Please consult Izumi International, Inc. if other voltage is required.

NEMA12 or equivalent rated enclosure. - Mounting: Mounting brackets per customer requirements can be configured.

CFA-F (for off-line monitoring)

This system to be used for off-line carbon fiber analysis. Purpose of use could include quality control,

research and development, customer process simulation, etc. The systems are configured to requirements,

therefore all units are custom designed.

- Width sensor: Via optical micrometer width sensor

- Fiber Width: 60mm maximum

(*) Please consult Izumi International, Inc. if wider rages are required. - Speed: Max 10m/min

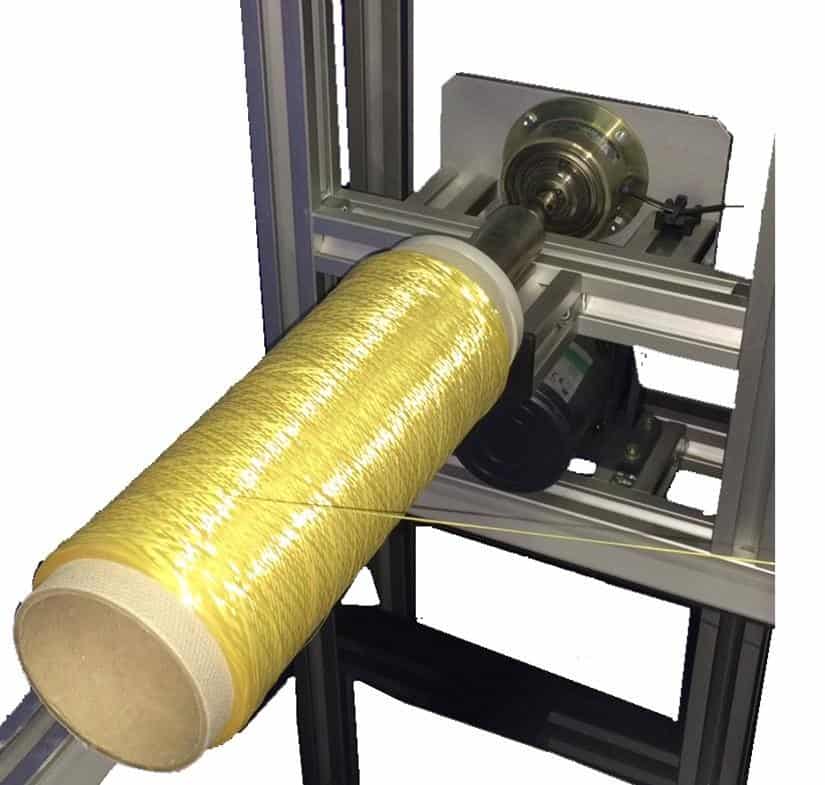

(*) Please consult Izumi International, Inc. if higher speeds are required. - Let Off Creel: Feedback tension controlled with tension sensor and electro-magnetic brake.

Standard tension is 2.0-19.0[N] control range via 20[N] capacity tension sensor.

Auto-traversing let-off maintains fiber width intact from original package. - Feed Rollers: 2-7 roller systems depending on tension requirements

- Take Up Winder: EKTW-C type carbon fiber take up winder for max. 250mm dia package.

- Options:

- Multiple tension zones for testing fiber under different tensions: each zone is controlled by a feed

roller and PID tension control - Polycarbonate enclosure to contain the fibers

- Gap detections in the fiber

- Filament breakage sensor (multiple if required)

- Other components can be added as required.

- Multiple tension zones for testing fiber under different tensions: each zone is controlled by a feed

- Operator Interface: PC based control system with self-standing enclosure

- Data Acquisition and Controls: Data logging to Excel style spreadsheets for analyzing

- Control systems available: Allen Bradley or Siemens

- Electrical: 220VAC three phase, 400VAC three phase

(*) Please consult Izumi International, Inc. if other voltage is required.

NEMA12 or equivalent rated enclosure.