PC Series Creel

March 23, 2022

TOP1000-HT

March 23, 2022BDT-X Bi-Directional Creels

Request Info & PricingGet a Quote

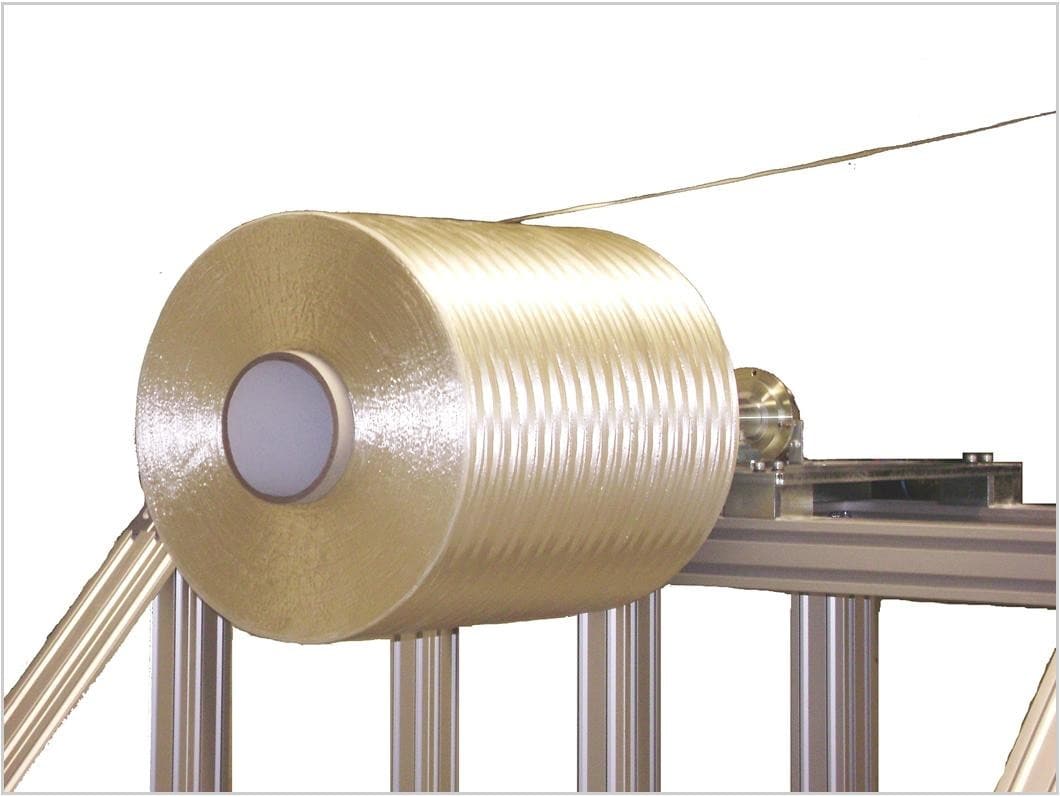

Bi-directional tension control for applications requiring let-off and take-back. Includes data monitoring/logging software for tension available

Type

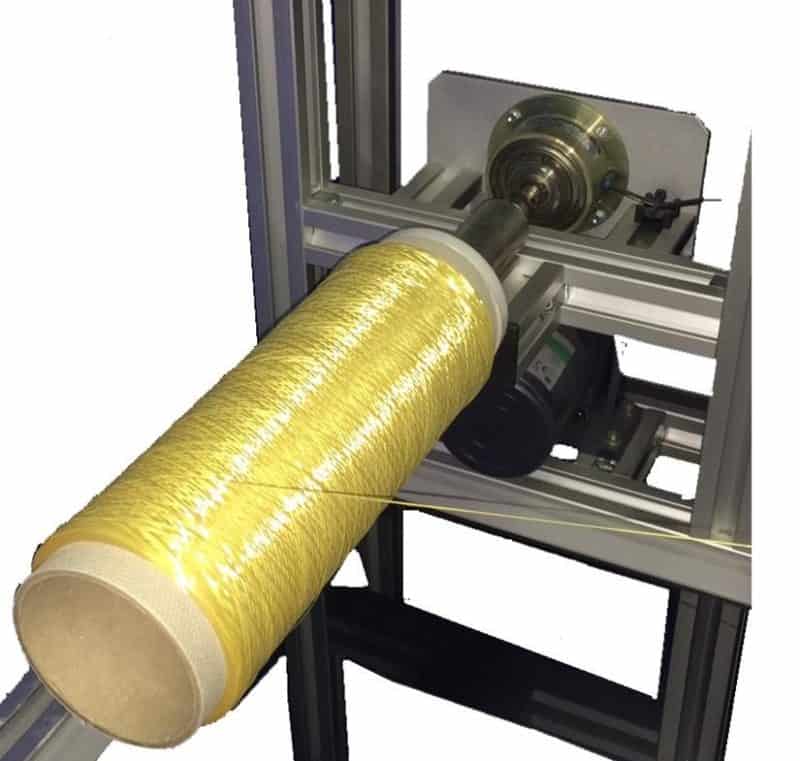

– BDT-CTF Negative feeding type

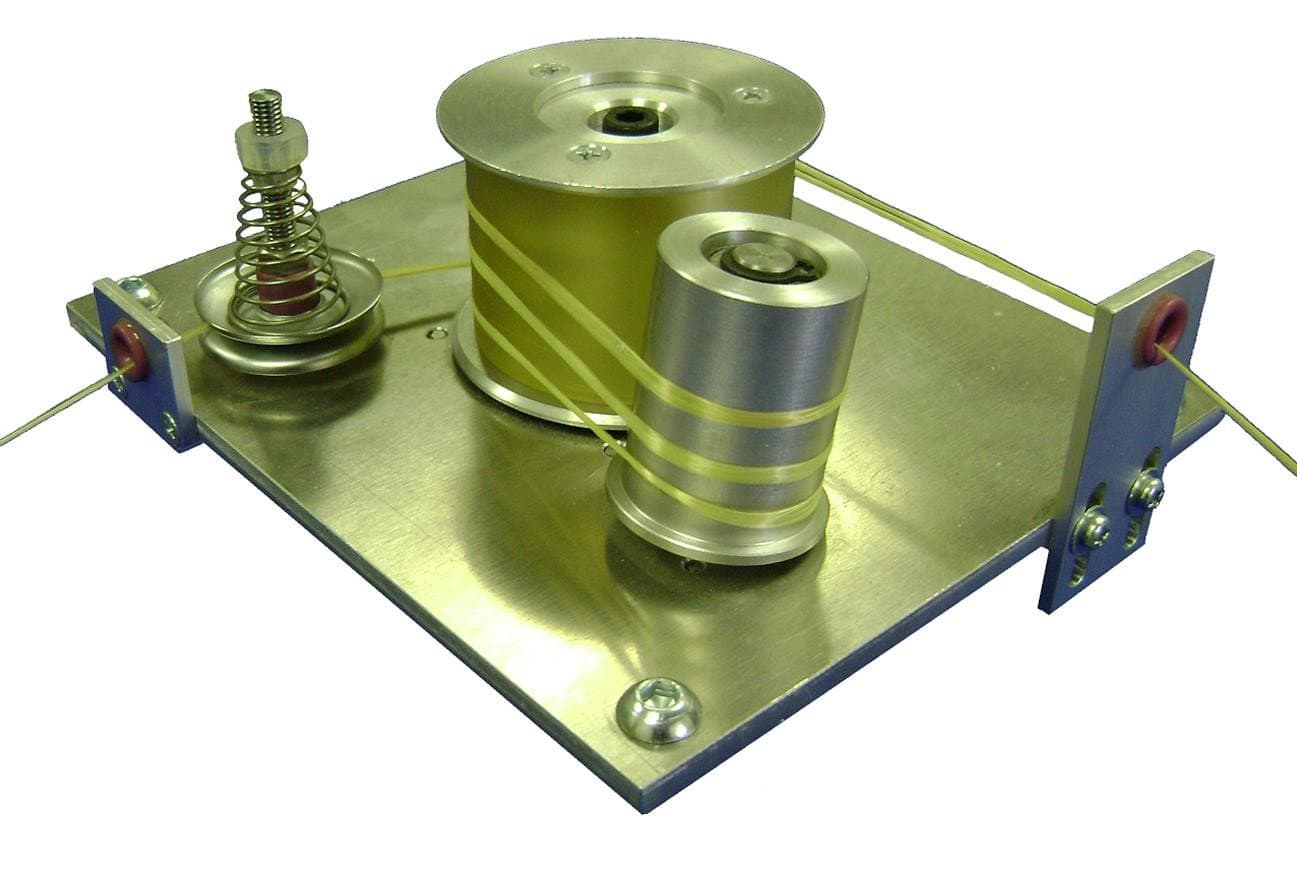

– BDT-SD Positive feeding type

Applications

– BDT-CTF for lower acceleration/deceleration, lower overall cost

– BDT-SD for higher acceleration/deceleration

Configuration

– BDT-CTF Motor and electromagnetic particle clutch

– BDT-SD Servo motor and tension dancer

Control

– BDT-CTF Via CTF tension controller

– BDT-SD Via servo drive PID

Tension Sensor

– BDT-CTF DTH type

– BDT-SD Optional DTH can be supplied

Tension Control Range

– Max 10,000 grams

Package Chuck

– Precision mechanical chuck for non-slip

Tension Monitor

– Can be equipped with tension monitoring and logging via PC