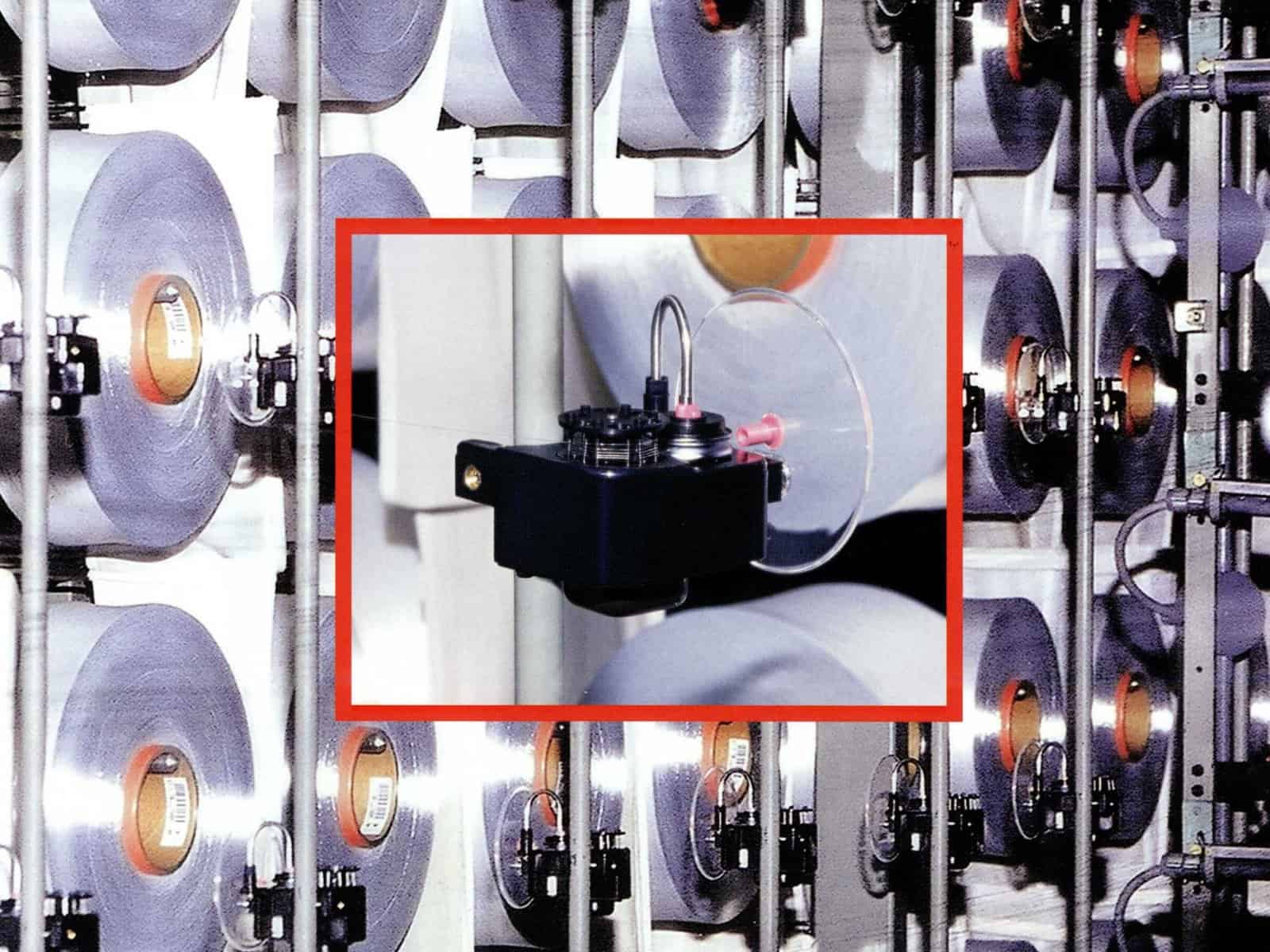

TOP1000 Tensioner

March 23, 2022KTAW

Request Info & PricingGet a Quote

The KTAW automatically rewinds carbon fiber or other fibers to empty cores, making smaller bobbins out of the full bobbin. This unit is especially useful for making small packages for use in large creel systems, dramatically lowering material costs by eliminating the need to load creel with full bobbins of carbon fiber.

Description

Yarn Kind

Carbon fiber, ceramic fiber, aramid, glass, etc.

Winding Speed

50~100m/min

Tension

50~1,200g via hysteresis tensioning brake

Pressure

500~4,000g with auto decrease

Standard Bobbin

76ø (ID)x83ø(OD)x280mm(L)

Maximum Diameter

125mm

Traverse Length

254mm

Power Supply

AC200V/240V/400V/480V 50/60Hz

No. of Spindles

One spindle / machine