Actuator

March 23, 2022

BDT-X Bi-Directional Creels

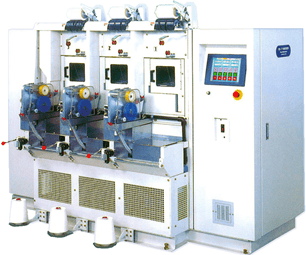

March 23, 2022Unisizer KS-7

Request Info & PricingGet a Quote

The KS-7 was developed to size various fibers, spun yarns (cotton, silk, hemp yarns, etc) as well as a variety of filament yarns to prevent fuzz, improve strength and sustain elongation properties.

Linking three processes (coating/sizing, drying, and winding) into one machine dramatically improves efficiency, quality, and contributes to saving space. The KS-7 is ideal for the recent trend of manufacturing a wide variety of fabrics in small lots, at minimum time, with frequent style change.

PERFORMANCE

Yarn speed (depends on yarn count): 50-550 m/min

Sizing pump flow rate: 15 L/min

Fan flow rate: 8-26 m/min

Drying chamber temp: 50-80°C

Sizing tank temp: MAX 80°C

Drying chamber yarn length: about 380m

Sizing tank capacity:20-40L

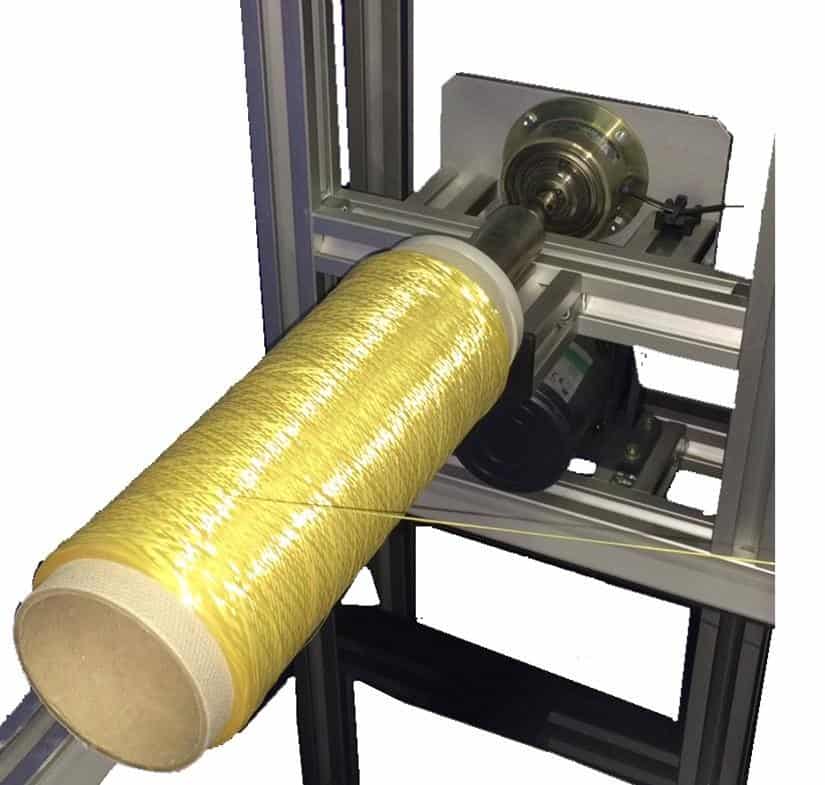

Winding system: Each spindle individual driven

Winding capacity: 1.0 (5 inch or 6 inch traverse) Optional cone winding also available

Stop motor function: On yarn breakage, yardage counter set point, and other miscellaneous alarms

Yardage counter: Each spindle equipped with yardage counter, yardage displayed on central panel

MOTOR & HEATER

Main motor: 1.5-2.2KW

Sizing pump motor: 0.4KW

Fan motor: 0.25 – 1.5KW

Drying chamber heater: 8-30KW

Sizing tank heater: 2-4KW

Steam arrangement capacity: 10,000-35,000Kea 1/H

Steam pressure: MIN 4.5 Kg/cm2

Voltage: Can comply with customer requirements (AC200V, 380V etc)

Total electrical capacity: 4.7 – 42 KVA

DIMENSION

Length: 3035-6455mm

Width: 1235mm

Height: 1700mm

Weight: 1390 – 2200kg

Color: Kaji Beige P22-344