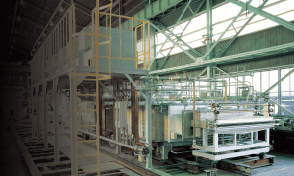

KYK furnaces have been the industry standard for carbonization furnaces. The highest quality carbon fiber has been produced from KYK LT/HT low temperature and high temperature furnaces for over 30 years. Production scale furnaces, as well as laboratory furnaces and pilot line furnaces for carbon fiber can be provided.

With the development of the first 3000°C furnace in the early 1980's, KYK has a rich history of developing UHT, or Ultra High Temperature Furnaces. These furnaces enable the production of high modulus carbon fibers.

These carbonization furnaces are equipped with a mesh belt to support the felt material for carbonization without applying tension.

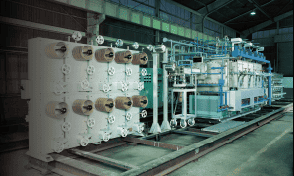

These furnaces are designed specifically for creating gas diffusion layer (GDL), required for fuel cell production. These furnaces are used to treat carbon cloth or carbon paper.

These furnaces are designed specifically for carbonizing activated carbon fiber.

These tray pusher type furnaces are most popular in applications for heat treatment of powder materials.

These tray pusher type furnaces are most popular in applications using a mesh belt furnace or batch type furnace.