These cells utilize 6-axis robots for various dispensing applications such as liquid gasket dispensing. Dispensing by means of 6-axis robots is an efficient platform for various dispensing applications, when a 3-axis tabletop robot does not provide the flexibility required.

Izumi International specializes in custom automation for dispensing. The automated cells are customized for the customer application, and incorporate 3 or 4 axis table top robots or 6-axis robots. Dispensing systems are incorporated per application, and can be traditional pneumatic dispensers or non-contact type jet dispensers. Cells can be physically enclosed or fit with safety curtains, depending on application.

These workstations can be customized for the customer’s specific applications, and can be modified after installation. Options such as table height adjustment, special lighting, gravity feed bin systems are available upon request.

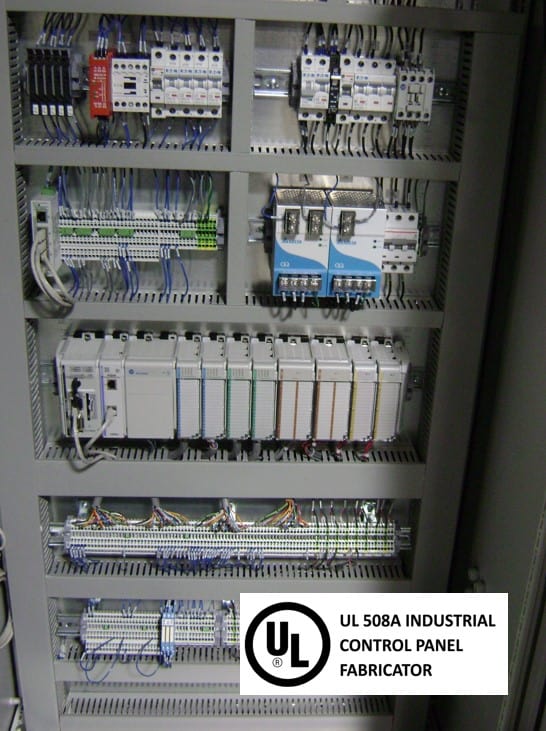

Izumi International designs and manufactures industrial control panels. All control panels for the equipment we provide are built in our in-house panel shop and we also […]

Karakuri automation systems require no electricity or electronic controls, utilizing the weight of the product itself to generate motion. It is a low cost solution for automated material handling.

Izumi International, Inc. develops and manufactures unique 3D dispensing equipment capable of printing living cells. The systems can be equipped with multiple dispensers for various biomaterials. Optional jet dispensers are available for high speed / non-contact dispensing. The systems utilize 3 axis positioning with optional 4th rotational axis.

Delta offers a complete solution to all your motor control requirements from simple V/F micro drives to advanced Field Oriented Control vector drives. With horse power ranging from fractional to 300 and input voltages from 110VAC to 575VAC, Delta drives provide a powerful and easy to operate motor control for your automation needs.

In automation design, every small detail has a big impact on the entire system, especially when countless accessories fill hundreds of catalog pages. Developing an accessory for every new application fundamentally contradicts our concept of a World Class product range. Our accessories are multi-functional and fit not only to an exactly defined component, but to all other components in the entire Modular Automation System.

Various mechatronics products use THK linear guide products. These units can be equipped with servo or stepper systemsfor off-the-shelf integration or can be supplied to work with drive systems supplied by the user.

The AeroJet is a non-contact jet dispenser designed for mid to high viscosity materials. Non-Contact dispensers enable dispensing from a distance, eliminate the need for z-axis adjustment, and contribute to high output.

The Awatraon3 is a centrifuge to remove bubbles from the liquid in syringes.

The Ball Screw is a high-efficiency feed screw with the ball making a rolling motion between the screw axis and the nut. Compared with a conventional sliding screw, this product has drive torque of one-third or less, making it most suitable for saving drive motor power.