EKTW-CAX

March 23, 2022

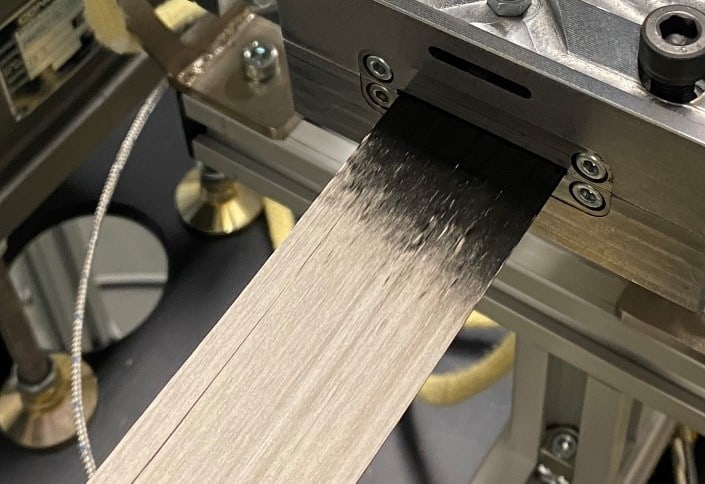

Carbon Fiber Thermoplastic Tape Extrusion Line

November 9, 20226-Axis Dispensing Robot Systems

Request Info & PricingGet a Quote

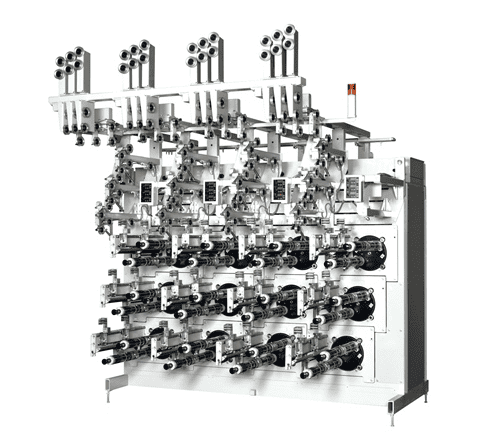

These cells utilize 6-axis robots for various dispensing applications such as liquid gasket dispensing. Dispensing by means of 6-axis robots is an efficient platform for various dispensing applications, when a 3-axis tabletop robot does not provide the flexibility required.

Categories: Automation Products, Custom Automation

Description

| 6-Axis Robot

|

Wide variety of FANUC 6–axis robots are available.

Selected by Izumi based on application requirements. |

| Tool changer | Tool changers are available for dispensing of multiple liquids. |

| Heating system | Syringe heaters for hot melt glues and plastics. |

| Enclosure | Robot systems are provided with full enclosure conforming to required safety standards and customized for each application.

Can be equipped with negative or positive pressure systems. |

| Gap / nozzle measuring | Nozzle position verification sensors for applications requiring accurate nozzle position monitoring.

Laser height detection on part to ensure gap distance for applications with critical bead width tolerances. |

| Dispense verification | Pass/fail verification after each dispense for quality control.

Record dispense measurements such as bead width, height or volume after each dispense for traceability of process. |

| Nozzles and cleaning | SS high precisions nozzles as well as disposable nozzles are available. |

| Fixturing | Fixturing is custom designed for each application. |