The Robotunits line consists of high quality extrusion and conveyor technology as well as safety fence and linear motion systems for material handling and assembly applications. The idea of the Robotunits modular automation system is to use the least possible number of components to offer a maximum of possible solutions. For Robotunits customers, this translates into time and cost savings in design, logistics, storage, training and assembly.

In automation design, every small detail has a big impact on the entire system, especially when countless accessories fill hundreds of catalog pages. Developing an accessory for every new application fundamentally contradicts our concept of a World Class product range. Our accessories are multi-functional and fit not only to an exactly defined component, but to all other components in the entire Modular Automation System.

Looking for a cost-effective belt conveyor system for your automation process? Robotunits offers a complete line of belt conveyor products engineered for high performance and reliability. Choose from a variety of configurations, belt types and motor speeds, and have the system delivered to you pre-assembled within one week. Robotunits’ belt conveyors integrate seamlessly with their extruded aluminum framing systems, and each system is thoroughly tested before delivery. For especially heavy or bulky loads, Robotunits also offers modular belt conveyors and timing belt conveyors.

The Robotunits material handling system integrates gravity feed conveyors seamlessly into the Robotunits aluminum extrusion system. This system consists of only 8 multi-functional parts, making design and assembly very easy. The widths are configurable for various size bins and totes.

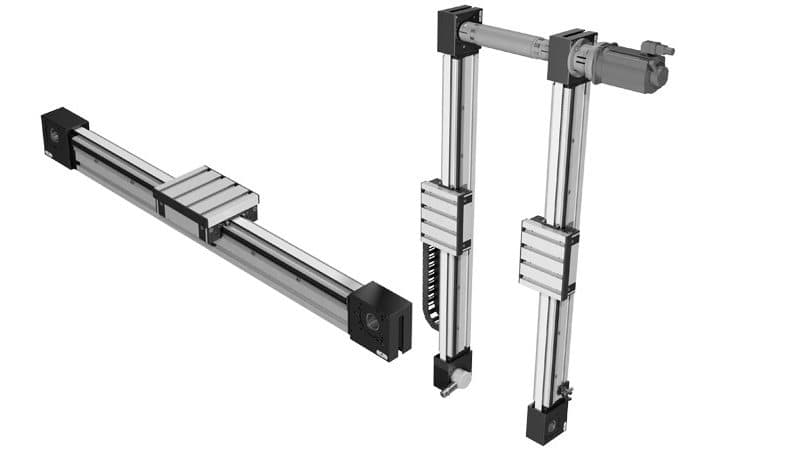

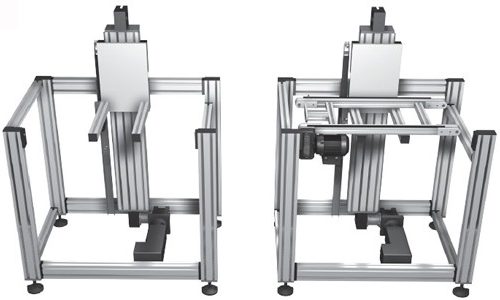

Keep your production line moving smoothly with the Robotunits linear motion system, offering strength, stability, and easy assembly with no welding. All linear motion components work seamlessly with the rest of the Robotunits extruded aluminum framing system, simplifying the assembly process and making it easy to incorporate a new station into an existing framing system. Choose from a variety of carriage types for different load weights, and various motor flanges and couplings for different torque requirements. You can design a custom linear motion system or lift station that meets your needs exactly, or choose from one of our standard designs.

Looking for an effective belt conveyor solution that can be implemented quickly and offer a quick return on investment? Robotunits offers service-friendly, modular belt conveyors that can be tailored to your organization’s exact requirements. Multiple widths, lengths, speeds, and sizes are available, and belts can be straight, curved, or on a gradient to create the perfect fit for your process. Your custom belt conveyor solution will arrive fully assembled and pre-tested for performance. The low-maintenance and easy-to-service modular design can stand up to harsh conditions, and it’s compatible with the full Robotunits extruded aluminum framing system.

Available Here

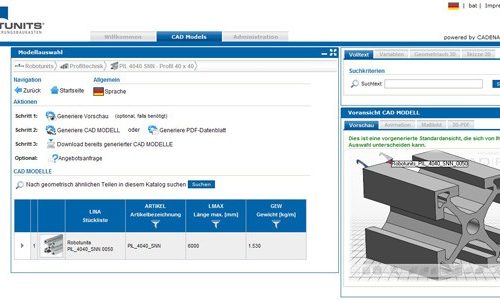

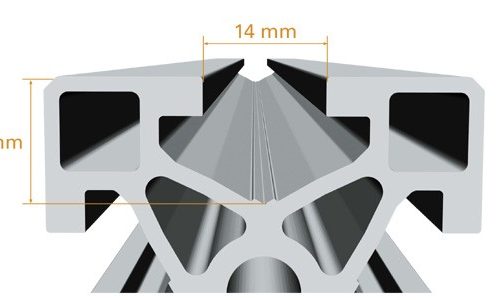

Looking for a sleek and practical framing alternative to welded steel? The extruded aluminum framing system designed by the experts at Robotunits offers near-endless design possibilities while requiring minimal assembly time. This all-in-one modular framing system features a variety of extruded profiles made of a durable aluminum alloy. The lightweight and easy-to-assemble configuration require no drilling or welding, and are have an anodized surface eliminating the need for painting.

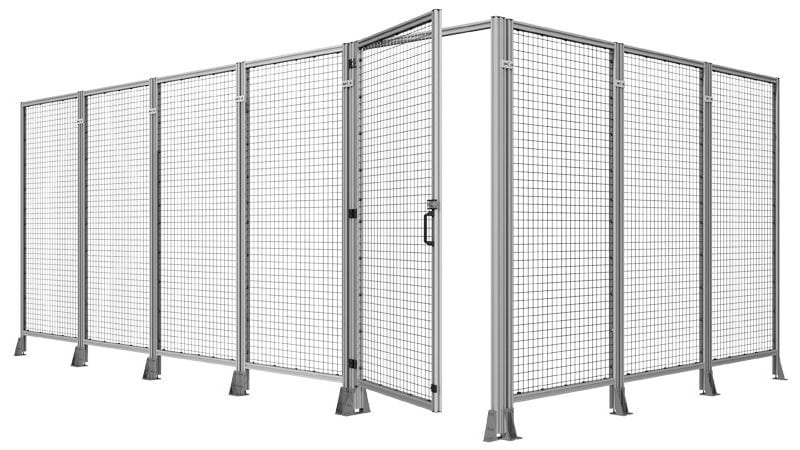

The demands for safety devices for the protection of people and machines have never be as tough as they are today. Production requirements that change at an increasingly rapid rate, as well as constant enlargements and adaptations require both flexible and time-saving safety systems. There is nothing as straightforward and as safe as the Robotunits safety fence system: completely prefabricated safety fence elements are ordered and can be easily and quickly assembled by just one person.

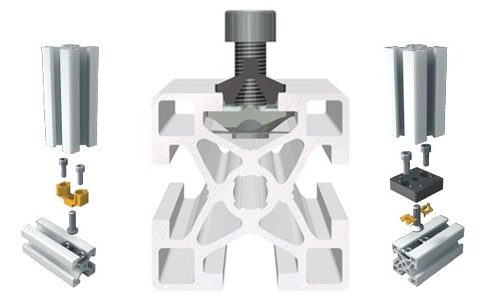

Robotunits’ unique, patented T-slotted fastening technology for its aluminum extrusion framing system requires no drilling or welding, and yet offers strength comparable to steel frames. Cut your assembly time in half with play-free, accurate and centrally aligned fastening. The Robotunits t-slotted system offers superior strength and durability in comparison with other aluminum extrusion systems.

For the transport of bulky and heavy parts, Robotunits offers the C4T and C8T timing belt conveyor. Standard lengths up to 12 meters are available. For this conveyor, a special, self-tracking timing belt that better withstands lateral forces than conventional belt is used. Parts travel on conveyor safely and smoothly since any interfering edges are removed. With the Robotunits timing belt, conveyor indexing and positioning applications are easily implemented conveniently and economically. Robotunits offers a wide range of different belt surfaces and profiles.

The Robotunits vertical lift actuators offer a quick and flexible solution to automated lift stations required throughout a material transportation system. The lift stations can be incorporated to lift a complete conveyor or series of conveyors as well. These lift stations can be equipped with guarding, stopping sensors, and other features as required. The systems can be servo driven lifting systems, VFD driven lifting systems, or constant speed lifting systems, depending on the application.