The Cross Roller Ring is a roller bearing with high rotation accuracy capable of bearing loads in every direction. Because it has orthogonally arranged cylindrical rollers, it can bear loads in every direction.

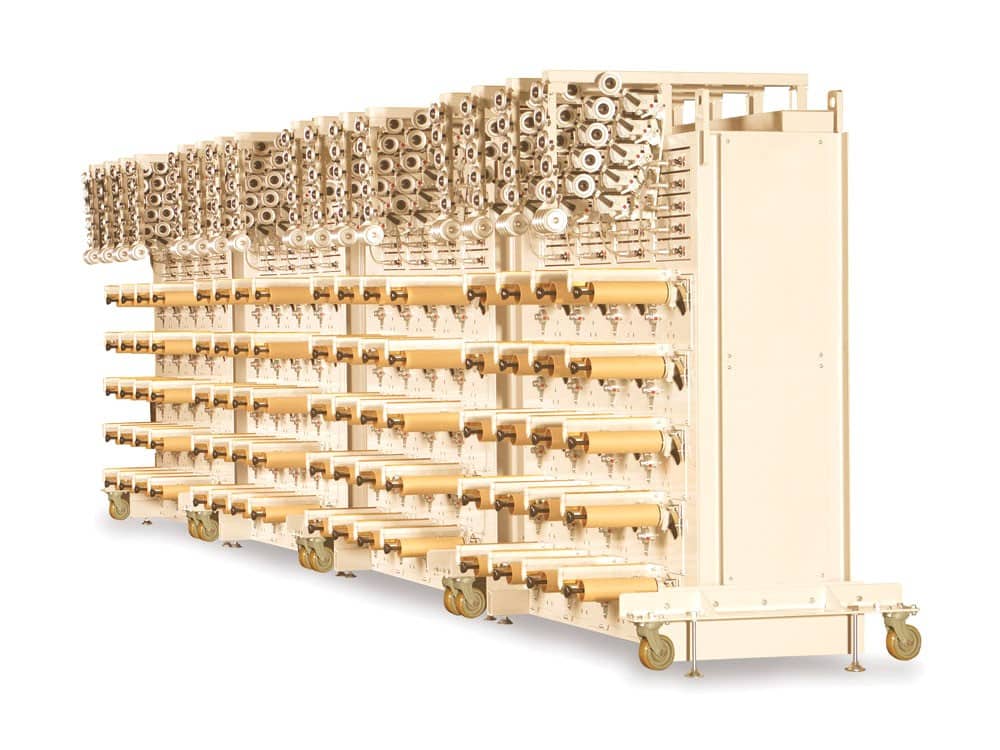

Off Loom Take Up for winding fabric from weaving machine to create large diameter rolls

The CyberJet2 is a non-contact jet dispenser designed for low viscosity materials.

The DTH tension sensor measures the tension of fibers or sheet materials with high levels of accuracy. Each unit’s microchip corrects mechanical deviations between units, giving your production line a cost-effective method of tension measurement with no calibration required. This tension sensor includes software (optional) that works with your existing PC to track and record data in an easy-to-read real time graph and also to Excel spreadsheet format. Multiple models are available to handle different fiber/web widths, tension ranges, and methods of data transmission.

$872.00 – $1,491.00

This is the standard range DTH sensor with ranges from 50 grams up to 3000 grams. Roller widths range from 2.5mm up to 42mm.

Select options This product has multiple variants. The options may be chosen on the product page$2,838.00 – $3,343.00

This is the high range DTL sensor with ranges from 5000 grams up to 20000 grams. Roller widths range from 22mm up to 62mm.

Select options This product has multiple variants. The options may be chosen on the product pageThis is the wide roller DTW sensor with ranges from 1000 grams up to 5000 grams. Roller widths range from 210mm to 610mm.

This is a customizable web tension roller and load cell combination suitable for up to 200kg of tension. Roller widths can be up to 3000mm wide.

$1,000.00 – $1,483.00

TAQ modules provide a means of data transmission to the DTH. The lineup enables various methods to transmit the tension data to a PC for live tension monitoring or tension data logging.

Select options This product has multiple variants. The options may be chosen on the product pageTake up machine for winding Pan or Pitch carbon fibers, aramid fibers and other high performance fibers. This winder has been one of the most popular winders for the carbon fiber production industry, taking up the carbon fiber as it is produced.

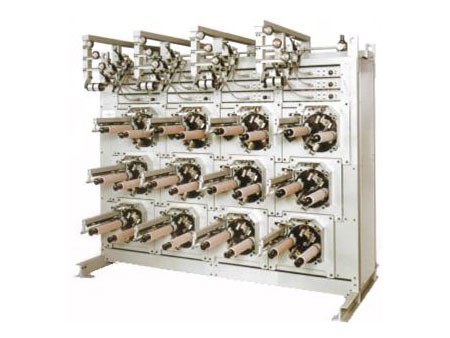

This machine in the KTW series offers a double spindle automatic bobbin change feature. This feature contributes to labor saving and space saving, for take up of continuous fiber production. The auto bobbin change feature activates once the package has reached a pre-set yardage.The unit is ideal for carbon fiber, as well as higher speed aramid fibers.

Model KTW-C is controlled by a torque motor with 5 head high layout pursues most economical investment of take up machine for winding Pan or Pitch carbon fibers, aramid fibers and other high performance fibers.