EMFT-BT is designed for winding flat materials without damaging, bending, or twisting the tape. This winder is used for materials such as tow-preg, tapes, flat yarns, slit film materials, slit prepreg.

When winding slit tapes, in many cases they are wound onto a narrow reel the width of the tape to prevent damaging the product. However, this results in a small amount of material being wound on the reel and subsequently decreasing efficiency in the following process. Traversing the material with a guide can put more material on the package, but can result in distortion, bending, or wrinkles in the product. winding. The EFT bobbin traverse winder can solve these problems and wind flat materials onto the bobbin. It traverses the bobbin assembly instead of the tape itself.

- The Flex-Winder is a programmable winder, enabling various wind patterns for different fibers on to various size bobbins. This single unit can accommodate most winding requirements, making it ideal for a wide range of winding processes.

The HBW is a bobbin winder for the leno (selvedge) yarn bobbins for weaving machines. The JBW is an automatic version for unmanned operation.

Izumi represents Kureha, who has been manufacturing rubber strips for more than 40 years. Kureha supplies rubber covering to many loom manufacturer's in Japan. Izumi has large inventory of roll covering in Greenville, SC. A wide variety of products to choose from, to fit every application.

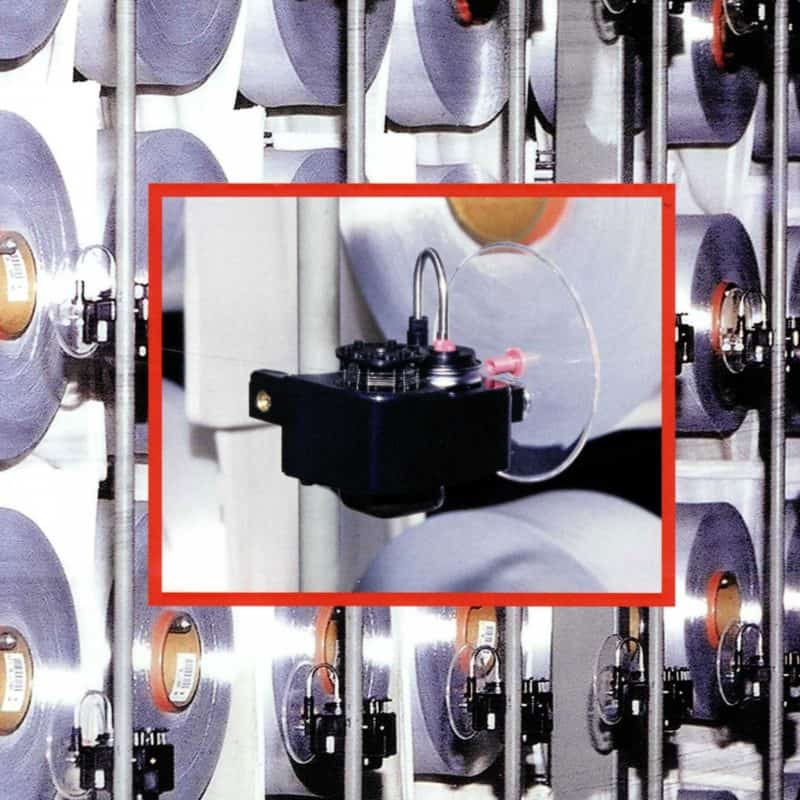

The TOP1000 is a magnetic type tension device designed especially for fiberglass tensioning on beam warping creels. The unit can also be used for various applications requiring fiber tension control.

- On board microprocessor corrects tension deviation within +/- 1 gram

- Unique tension wheel eliminates yarn damage and filament breakage

- Non Contact Hysteresis Brake

- Tension conol unit conols 20 tension devices

- Simple operation

- Programmable at 1 gram intervals

- Because of no secular change, consistent high accuracy is maintained even after long use

- Internal Gearing Type Hysteresis Brake Mechanism offers small moment of inertia and higher RPM operation

- No joint on the Hysteresis material for smooth emanated torque

- Microcomputer equipped Controller

- Corrects each unit deviation by microcomputer

- Simultaneous remote tension setting for all positions

- Parallel wiring connections saves on wiring material

- Yarn Break Detection Function (optional)

- Yarn Length Measuring Function (optional)

These tray pusher type furnaces are most popular in applications using a mesh belt furnace or batch type furnace.